info@snmhardware.com 008618965075392

Torsion spring have a number of design elements to consider when working with a torsion spring design. The following is a list of key design considerations when working with torsion springs in your application:

- Torsion spring loads should be specified at a fixed angular position and not at a fixed deflection from the free position.

- Torque spring testing is not easy to perform. Torque measurements for torsion springs can be taken, they may be inconsistent.

- Torsion spring inner diameter reduction and potential binding should be considered in your application.

- For torsion spring applications that require minimum hysteresis (load loss) torsion springs should be designed with space between adjacent coils to reduce frictional losses.

- A torsion spring should always be loaded in a direction that causes its body diameter to decrease. The residual forming stresses are favorable in this direction, but unfavorable when the spring is loaded in a direction that increases body diameter.

- Clearance must be maintained between the mandrel and the torsion spring at all times to prevent binding. The ideal mandrel size is equal to, or slightly less than, 90% of the inside diameter. when the spring is fully deflected (minimum diameter). Mandrels significantly smaller than 90% should be avoided to prevent buckling during large deflections.

- Most torsion springs are close wound; therefore, the torsion spring body length will increase when a spring is deflected in the direction that will reduce the coil diameter. In tight housing designs, this increase should be considered.

- Torsion spring direction of wind must always be specified for a torsion spring.

You can determine direction of wind of a torsion spring by simply holding it in your hand with your fingers placed around the outside of the body and your thumb pointing straight up. If the last coil ends in the same direction that your fingers are pointing, that is the hand (direction of wind) of the spring. The wind of the torsion spring can be right hand, left hand, or double torsion. Good design dictates that torsion springs should be used in the direction that winds the coil.

Common Torsion Spring Leg Configurations

Torsion springs can be designed and manufactured in wide range of torsion spring end and leg configurations. Special torsion spring leg configurations are available on request. When designing torsion spring ends, it is important to consider that bends, loaded to decrease their radius of curvature, have favorable residual stresses. They can operate at higher applied stress levels than bends that increase the radius by loading. Frequently, torsion spring performance is limited because the sharply bent ends have greater stress than the body.

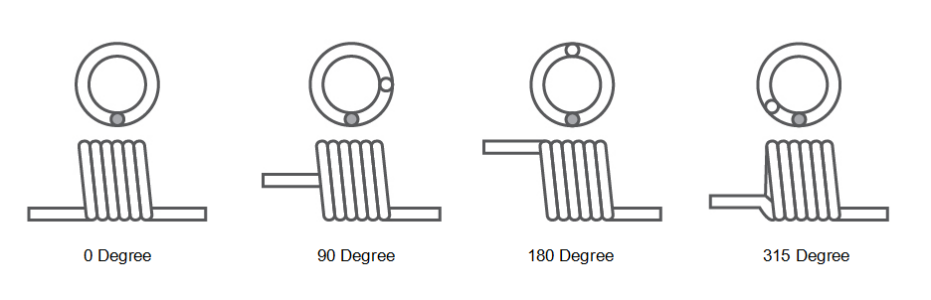

Axial Torsion Spring Leg Configurations

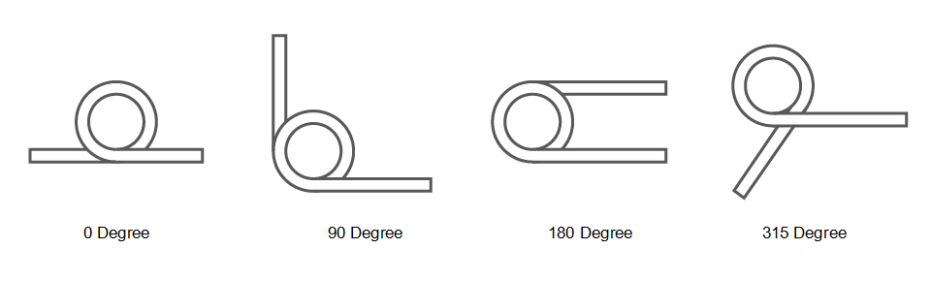

Tangential Torsion Spring Leg Configurations

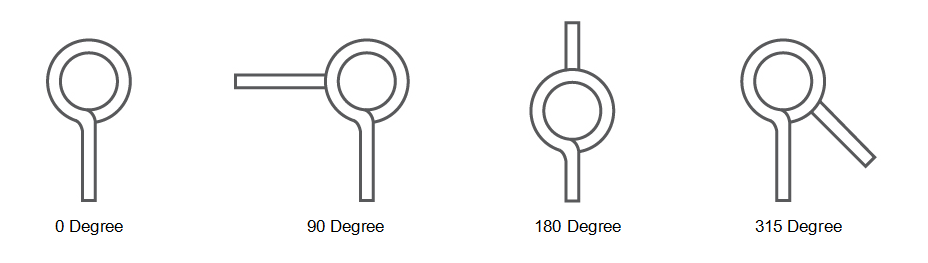

Radial Torsion Spring Leg Configurations

Radial Center Over Tangential Torsion Spring

Double Torsion Springs

Special types of torsion springs include double torsion springs and springs having a space between the coils to minimize friction. Double torsion springs consist of one set of coils coiled right hand and one set of coils coiled left hand. These coils are connected, usually with an unwound section between the winds and work in parallel. The sections are designed separately with the total torque being sum of the two.

SNMHardware provides many types of torsion springs and also undertakes the manufacturing of customized torsion springs.